Model VKR Knuckle-Rake Bar Screen

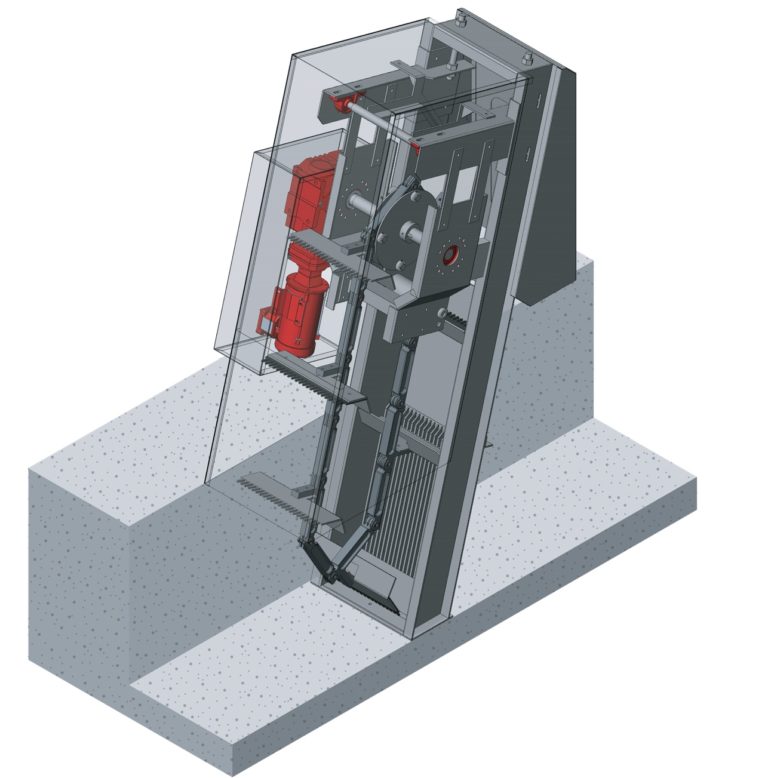

Vulcan brings the simple design of the Model VKR Knuckle-Rake Bar Screen to market for those owners seeking a “budget” screen that can do the job right. But don’t worry, “budget” doesn’t mean flimsy or cheap. Vulcan designed this screen to handle debris found in wastewater, storm water and combined sewers of smaller systems with lower flow rates, but with the same challenges seen in higher flow systems. The Model VKR Screen is an automatic, self-cleaning mechanical bar screen customized for existing channels or new construction. Whether at pump stations, intake structures, or wastewater treatment plants, the Vulcan Model VKR Knuckle-Rake Bar Screen provides consistent, low maintenance and economical screenings removal.

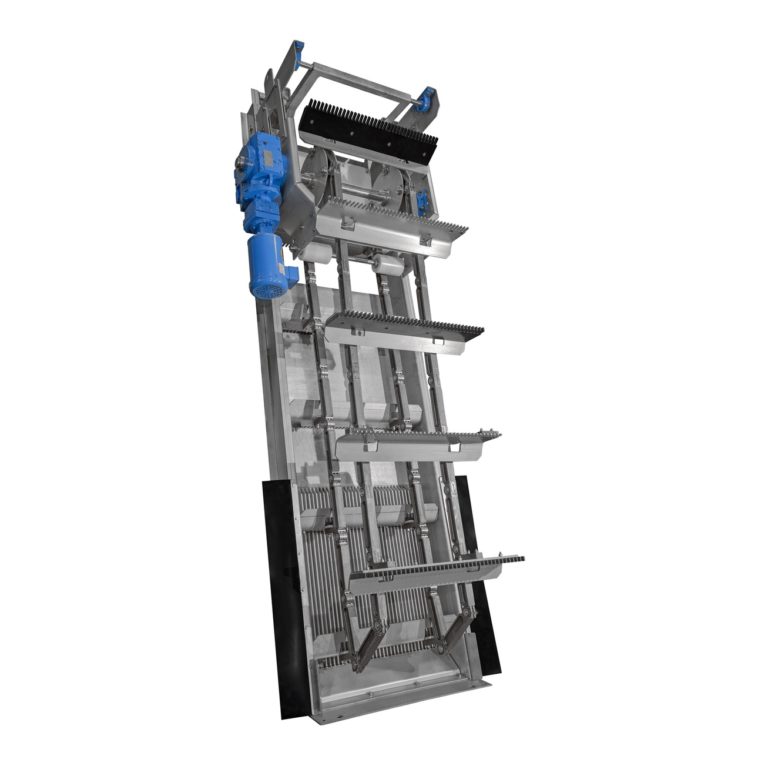

VKR Knuckle-Rake Bar Screen Design Features

Big or Small. The same tough Vulcan standards apply.

- Unique knuckle chain “link” drive system eliminates lower sprockets or guides in the waste stream flow.

- Installs in channel widths from 12 in to 4 ft and depths to 20 ft. Typical setting angles between 60 and 75 degrees.

- Single or dual “link” drives available based on channel width and depth.

- Bar rack clear spacing from ¼ in to 3+ in.

- Scoop shovel shaped rake shelves for high solids loading in each pass resulting in no loss of materials collected by the rake.

- Brushless, water-free automatic discharge wiper eliminates brush adjustments and messy discharges. Self-positioning wiper without shocks or springs includes easily replaceable UHMW polyester wiper blades.

- Frame mounted integral covers and enclosed discharge chutes available for maximum odor control and outdoor installations. Fit and finish provide a “good looking” screen.

- Fully-automatic, two-speed operation with UL-approved controls manufactured at our factory.

- Increased number of rakes combined with low speed operation promotes long equipment life.

- Choice of TEFC or explosion-proof motors—typically only require energy saving 0.5 HP motors for most applications.

- Range of simple controls to SCADA interfacing, Vulcan can do it all. Just tell us what you need.

- Choice of 304 and 316 stainless steel construction, including the “Quad-Pin” drive sprockets. Links constructed of cast stainless steel comparable to 316 stainless steel corrosion resistance.